Customized Sizing and Shapes for Nylon Netting: A Strong and Durable Choice

Gourock specializes in supplying our customers and clients with netting products and custom netting applications that are prepared per-invoice, built to the custom sizing and dimensional requirements needed for the order and project. In many cases, the nylon nets that are needed for a particular project are well-suited as 2-dimensional rectangular or square shapes, built to whatever height, width, or length requested. Some good examples of this sort of netting panel supply include golf driving range barrier nets, spectator protection nets at stadiums, bird exclusion nets surrounding warehouse openings, debris cover netting over ponds, and many other applications and situations. Over the many years in the custom netting industry we have gained supply experience in thousands of different applications and uses!

But in addition to the great availability of custom-sized barrier nets and netting panels, Gourock also has availability for netting productions that require a lot more specialization and finished design specifications. Generally speaking, there are many nets that need to have very specialized shape, construction, and netting configurations in order to be properly functional at our client’s locations and intended purposes. We see this often with netting enclosures, tapered or angled nets, multi-sided netting panels, and custom netting applications that have special seaming or sewing considerations. Because the use of netting is such an efficient and dependable solution to a huge number of different industries and uses, we have a ton of experience with very specialized netting applications – and providing the high quality nets to accomplish the job.

Built from premium netting materials, including DuPont® Type 66-728 Twisted-Knotted Nylon Netting, Gourock.com is your go-to source for 100% Made in USA netting products – with quick fabrication lead-times and top quality craftsmanship and service. Throughout the Gourock.com site and within this company blog we outline many examples of unique custom nets that have been administered and shipped out over the years – and we strive to communicate to you the different possible options and build details that are available to provide. Here are three examples from the last month that really help demonstrate some of the netting productions that we deal in on a weekly basis – and if you have some inquiries into custom netting for your own projects, always feel free to get in touch with Gourock and we can correspond about your needs!

Custom Netting Applications

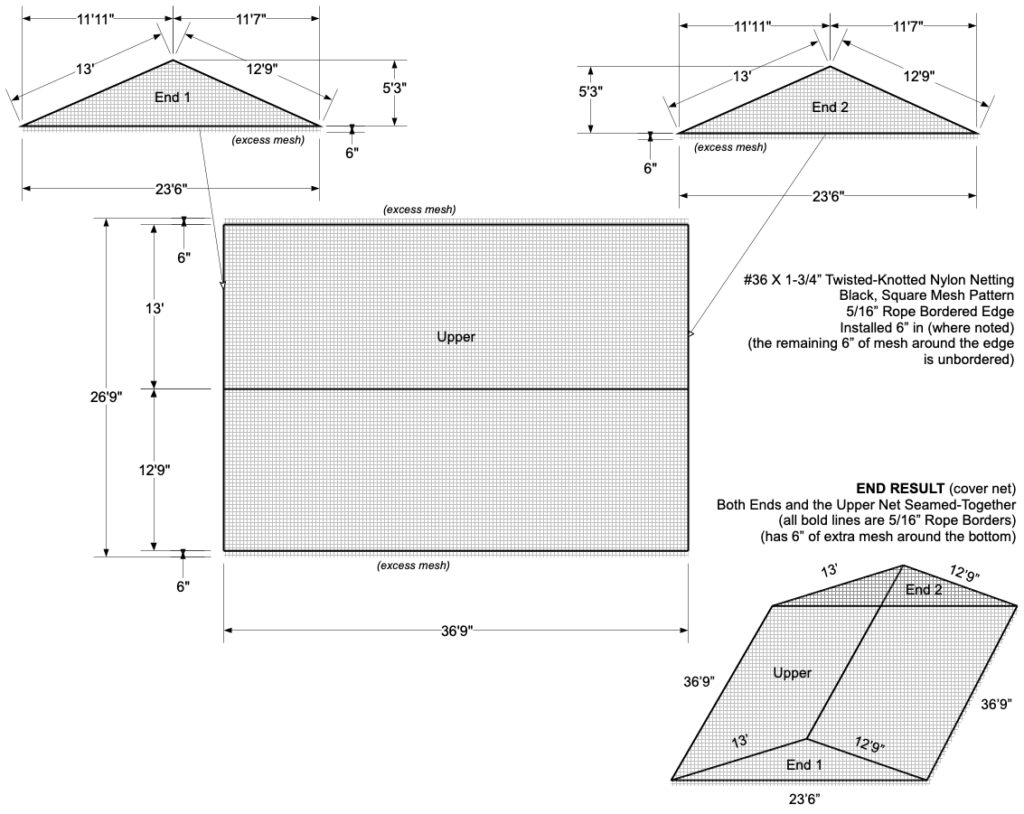

The first recent example of a very custom netting production and design is this project built from #36 X 1-3/4″ square mesh twisted-knotted nylon netting. Our client was at a municipal location, and required a custom built cover net to fit with their existing framing structure that was already on-site. The purpose of the netting is to extend over their framing structure, which spans over a portion of a fish hatchery – in order to keep predatory birds blocked from accessing the water and fish within. Over a series of years they had utilized some basic netting sections and then spent time pulling and adjusting them over the framing – which proved to be relatively arduous over time. So when the opportunity to replace the old netting arose on their end, we were able to closely work with them on a series of requested designs and sizes – and get the final product squared-away and produced for their use. This netting solution dramatically increases the efficiency of their installation every season, and is built from the very robust 2.5mm twine thickness DuPont® nylon – so resiliency and durability over time is assured.

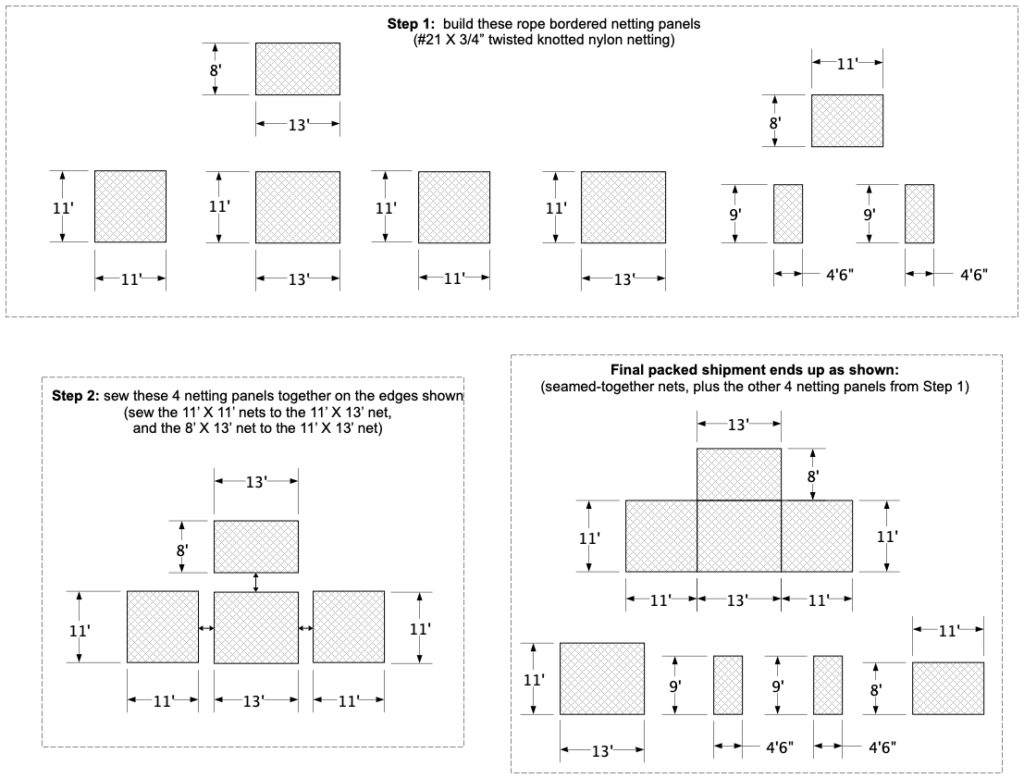

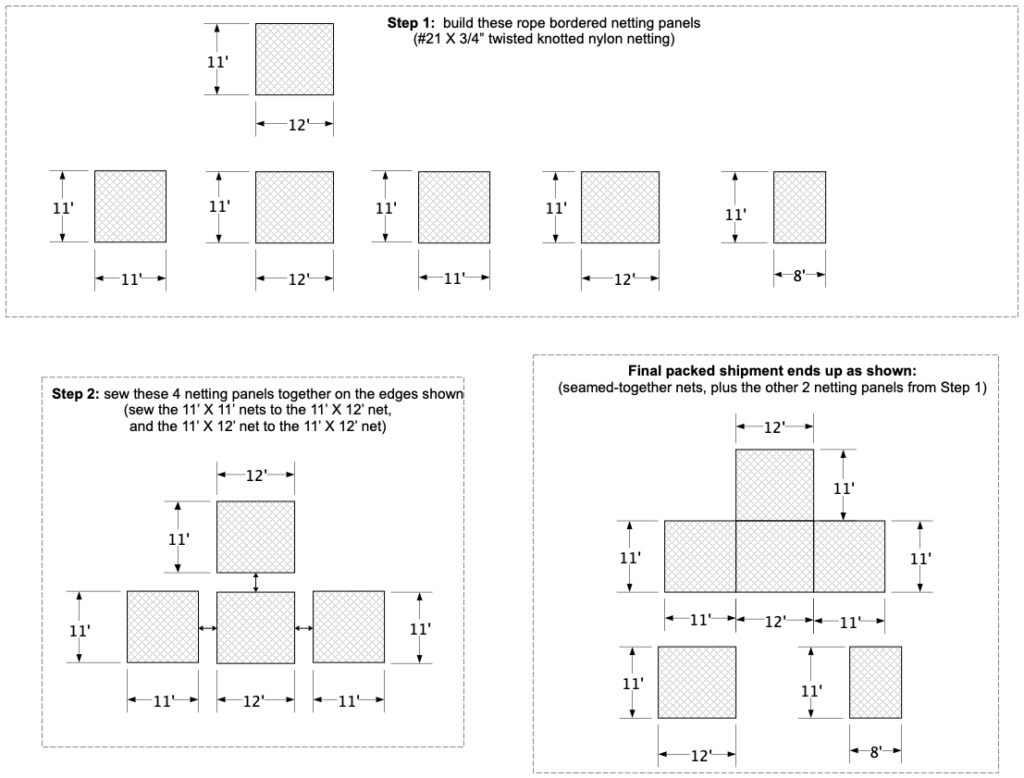

These next two custom netting application examples were for the same client, who was a commercial golf customer that was installing golf driving nets at an indoor location within their golf training facility. Constructed to a series of sizes, assembly configurations, and shape needs that were requested by our client, these final netting designs were fabricated in order to make their own preferred installation techniques and processes work well. Generally speaking, these #21 X 3/4″ DuPont® knotted nylon nets were to be layered/suspended within some existing framing structures that they already had available on-site. Their preference for hanging the netting was to have an end result of a couple box/cage nets to drive golf balls into, and having the netting prepared in a way that allows it to fold-together into a box-shape was their request. Also incorporated were some additional netting panels to be used as secondary layers of impact/baffle mesh, in order to double-up the inside back-end of the hitting area. The #21 X 3/4″ knotted nylon is a fantastic golf impact containment netting material, with high tensile rating and high abrasion resistance – and these nets were all hand-bordered and prepared with 5/16″ braided Dacron® rope edges.

As you are doing your research into netting supply, custom netting applications, and preparing your project for netting requirements – absolutely feel free to get in touch with us here at Gourock. We can always take a look at what your requests are, or assist with any questions or inquiries that you have about netting and netting fabrications.

We greatly appreciate all of our great custom netting customers and clients, and value your business very much! And thanks again!

- Josh Grzyb @ Gourock.com

3 thoughts on “Custom Netting Applications: Meeting Needs With Unique Designs”