Custom Nylon Batting Cage Nets

For years, Gourock.com has been supplying commercial facilities, colleges/universities, city municipalities & schools, recreation departments, and residential installations with highly customized and one-of-a-kind netting projects. Custom netting enclosures and projects feature the highest quality nylon sport netting, DuPont® Type 66-728 Twisted-Knotted Nylon, as well as premium construction materials like Dacron® Ropes and nylon tying twine. Hand-built and 100% USA Made, your custom project can be produced with expert netting knowledge and craftsmanship.

Custom Baseball Batting Cage nets can be quoted using the Custom Batting Cage Calculator above or you can Contact Us to submit your dimensions, netting type request, and forward over drawings/diagrams for more complex jobs.

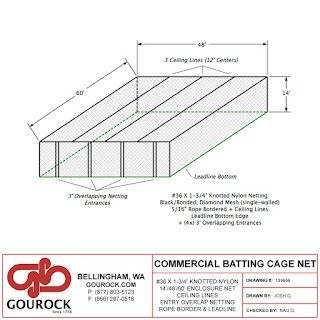

Below are drawing examples of various custom projects facilitated by Gourock, Inc. (designed/drafted by Gourock based on customer-provided information, then put into production and delivery). See also our company blog for additional custom batting cage netting examples.

NETTING FABRICATION DETAILS:

Gourock Custom Batting Cage Nets are 100% Made in USA from the highest quality nylon netting material, DuPont® Type 66-728 Twisted-Knotted Nylon. Nylon Batting Cage Nets are constructed with a fully-enclosed netting design incorporating the top/ceiling, side walls, and end-panels all seamed together and ready to hang/install as a complete 3-dimensional netting product. Featuring 1-3/4” mesh baseball netting, diamond mesh pattern, and black coloring with UV stabilization and protective bonding – these custom batting cage nets are well suited for all outdoor and indoor installations.

There are 3 nylon netting twine thicknesses available to select from:

Nylon batting cage nets are rope-bordered on all 4 vertical corners and the entire top perimeter, with a center-ceiling rope running the length of the cage netting. Nets are hand-prepared and bordered with 5/16” Braided Dacron® Rope (3000+ lb./break).

There are 3 ways that the bottom edge of the batting cage enclosure net can be supplied:

- No Bottom Border Material/Rope (if ordered as-is)

- 5/16” Rope Border Bottom Edge (optional)

- Weighted-Rope (Leadline) Bottom Edge (optional)

The standard construction has loose/excess meshes along the bottom in order to properly contain balls within the enclosure. Adding a rope border to the bottom edge is great for a finished appearance and for extra material along the bottom. The weighted-rope bottom ensures that the netting stays weighted to the ground, preventing any loose/hit balls from rolling underneath.

**Consider having the net constructed 6”-12” taller in height compared to where you expect to hang it from, allowing for some netting to pool at ground level (helpful for keeping all balls contained).**

For extra-wide batting cage nets, you are offered the option to add rope bordered divider panel nets to the order. These nets are constructed to the same height and length as the enclosure netting, and are included separately. Divider nets allow you to divide the overall enclosure area into narrower individual tunnel areas as needed.

There are many custom features that you can also have built by Gourock. We have supplied hundreds of custom batting cage nets that include custom aspects such as 3’ overlapping entrance doors, loose/open end-panels, additional ropes or connection points, tapers and angles, notches and irregular shapes, custom dimensions, double-ends, portals, and many other unique requirements. Feel free to Contact Us and submit a quote request for something more customized and we’ll get it done for you.

**Custom nylon batting cage nets are fabricated per-invoice and have varying production lead-times to be ready to ship out. Most are finished and ready to depart within 3-10 bus. days, with some extra-large sizes or multiple quantity orders taking a bit longer (within 2-3 week avg.)**

-Josh Grzyb @ www.gourock.com