Indoor Softball Netting – Customer Photos

A recent customer of ours finished up installing their netting at their indoor softball practice space, and it looks like a really nice and functional training zone! Mark with Cedar Lake Girl’s Softball in Cedar Lake, IN was great to work with for the organization’s custom netting needs. He had already retrofitted the walls of the indoor hitting area to incorporate some heavy conveyor-belt fabric that was repurposed as hanging wall-protection material, and they needed batting-cage style containment netting for the inner volume of the space.

Gourock.com specializes in the supply of custom softball barrier netting and batting practice nets, and we were able to get the Cedar Lake organization the exact sizing and features they needed for their intended installation and usage. The netting supplied for this job was the heavy-duty #36 X 1-3/4″ (2.5mm, 381 lb./tensile) DuPont® Type 66-728 Twisted-Knotted Nylon. This is a 100% Made in USA netting option available through Gourock.com that is prepared to any particular dimensions that you require. The #36 twine thickness is very popular for organizational-style batting cage nets, as well as baseball and softball applications that subject the mesh to continuous impacts and abrasion.

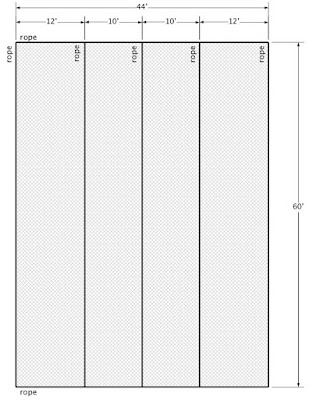

The plan was for them to install tensioned wires from wall-to-wall across their space, and then clip the netting underneath the wires. They wanted a continuous netting panel that could incorporate both side walls and the upper ceiling netting all into piece. We had 5/16″ braided polyester rope bordering sewn-in around the entire perimeter edge, and then also installed through the interior area of the netting to line-up with the spacing of the wires. That way there is a nice solid rope attachment point to clip the netting to the wires with, allowing for a very efficient and functional netting installation. In this case, the overall netting panel was produced to be 44′ wide X 60′ long, with 3 intermediate ropes running through the netting at 12′ and 10′ intervals.

In addition to the surrounding containment netting, they also wanted to incorporate a sliding divider panel net that will be used to divide the enclosure area into separate training/hitting tunnels. The divider panel net was built from the same #36 X 1-3/4″ knotted nylon netting (with rope bordering), and was fabricated to the sizing of 12′ high X 60′ long. It is clipped to its own independent wire that runs through the enclosure area, which allows for it to be slid back-and-forth “curtain-style” when needed.

All nets were supplied with 1/4″ steel snap-hooks to clip the netting to the wires with.

Here are some shots and photos of the netting installation that were forwarded over to us here at Gourock from Mark and his team at Cedar Lake Girl’s Softball. Looking really great guys! We very much appreciate your business and it was very nice working with you!