FAQ, Custom Netting Frequently Asked Questions

A helpful review of several netting questions, clarifications, ordering details, and product information.

To further assist you with research into custom nets and netting solutions, this page is a helpful online resource to reinforce your product knowledge and familiarity with Gourock. Within each main topic category please click to view individual questions/answers, or scroll down to read all FAQ's in continuity. For additional inquiries or clarifications, always feel free to use our Contact Page to submit other questions you may have as well - thank you!

ABOUT GOUROCK

What does Gourock specialize in?

Where are you located and what are your business hours?

Who are your customers?

How are orders placed?

Are you available to correspond about particular inquiries?

NETTING SUPPLY

What types of netting materials and products do you supply?

How are the different netting types specified/identified?

What type of netting do I need?

Can any sizing of netting be ordered?

What are the minimum order details for custom built nets?

What is the difference between Square Mesh Pattern and Diamond Mesh Pattern?

How are nets bordered or finished around the perimeter edges?

What are the differences between Golf Barrier Netting and Golf Impact Netting?

Can your netting be used for outdoor and indoor applications?

What is the average functional life expectancy for different netting types?

What color selections are available for different netting types?

Do you offer netting repair services or sell used netting?

Do you have specification sheets available for the different netting and mesh products you supply?

I have some unique sizing, shape, or design needs for my nets - how can I have those features included?

CUSTOM CAGE NETS

What are custom cage nets, and what are they typically used for?

Can any sizing be ordered?

What netting types are used to build custom enclosures and cage nets?

Can batting cage nets also contain golf balls?

Do cage nets come with frames or associated installation parts?

How long does it take to build and ship a custom cage net?

I have more customized design needs for my cage netting project, how can I have those features included?

HARDWARE AND ACCESSORIES

What types of netting installation hardware items do you offer?

What are your hardware parts usually used for?

GENERAL QUESTIONS

Where are your nets made?

How long does it take to receive my order?

Do you offer installation services or on-site work?

Do you sell poles, posts, frames, or framing parts?

Where can I find poles or posts for my netting project?

What is the return/exchange policy on purchases?

How are nets packaged and shipped, and where can they be shipped to?

Are there warranties applied to any of your custom netting products?

What purchasing opportunities do you offer for municipal, organizational, industrial, and vendor-focused clientele?

Can I have samples of the different netting types mailed to me?

Do you accept photos of our installation to be posted on your website?

ABOUT GOUROCK

What does Gourock specialize in?

Gourock specializes in the production and supply of netting and custom nets. Offering a robust product line of premium quality materials and mesh selections, featuring expert manufacturing and craftsmanship, we offer netting solutions that are custom built according to the sizing needs that our customers require for their projects. Gourock.com is your factory-direct source for durable netting products - servicing a wide array of industries, applications, and very appreciated clientele.

Where are you located and what are your business hours?

Gourock.com is located in Bellingham, WA. Office hours are Monday - Friday (excluding major holidays) with customer service availability between 9 am - 4 pm Pacific Time Zone.

Gourock is the trusted netting supplier for thousands of individuals, commercial entities, municipal and scholastic locations, governmental agencies, professional organizations, contractors, and private property owners. We are a leader in direct-to-consumer netting supply, offering premium quality netting products to customers of all types. Whether you have project requirements for large volumes of specialty nets, or a single piece of bulk mesh, Gourock.com is your factory-direct source for custom netting. With over 25 years of e-commerce expertise, we are consistently refining and improving our customer’s experiences within the netting marketplace. Premium products and professional service are two of the reasons why Gourock.com is the preferred netting supplier for large volume organizational clients, private individuals, and every type of netting customer in-between.

Custom netting orders are conveniently placed directly through our online store, as well as via personal correspondence with our sales staff. The Gourock.com online store includes convenient Custom Netting Calculators that allow our customers to specify their own dimensions, mesh selections, finishing border choices, and check out directly online. In addition, we also personally assist hundreds of customers with their custom netting orders via phone and email correspondence. And thirdly, we have many respected commercial, organizational, and vendor clients that facilitate their business via purchase order or similar account management arrangements.

Are you available to correspond about particular inquiries?

Absolutely! A large amount of our continued business starts off as a general inquiry into how custom netting will best suit a project need. We consistently work personally with potential customers regarding their questions and quotation requests - and remain available to assist all the way through the processing of the order invoice. It is our pleasure to offer professional and efficient service, allowing you to source the best custom netting solutions for your projects.

NETTING SUPPLY

What types of netting materials and products do you supply?

Gourock specializes in top quality netting productions, featuring materials including Nylon, Kevlar, HMWPE, Polyester, and HDPE. Generally speaking, netting is a type of product that is created from a variety of twine thicknesses, mesh sizes, and overall fabrication details that are often defined by the material and the looming/production processes. Gourock offers a robust selection of netting choices, which are used for a very wide range of typical uses. For context, our current custom netting product line includes:

DuPont® Type 66 Twisted Knotted Nylon Netting

Available in twine thicknesses ranging from #12 up to #72, and mesh sizing from 3/4” up to 4”. 100% Made in USA. Durable and dependable combination of high tensile strength, abrasion resistance, and knotted mesh construction. Well prepared for outdoor UV and moisture exposure with treatments including latex/urethane bonding, dispersion dying, and asphalt tarring (on 1” knotted mesh).

Nexus® Type 6 Twisted-Knotted Nylon Netting

Available in #36 Perma-Black twine thickness and 4” square mesh size. 100% Made in USA. Durable and dependable combination of high tensile strength, abrasion resistance, and knotted mesh construction. Well prepared for outdoor UV and moisture exposure with solution dyed Perma-Black nylon filament and latex/urethane bonding.

201D Braided Knotless Type 6 Nylon Netting

Available in 210D/80 and 210D/120 with square mesh sizes of 1” and 2”. 100% Made in USA. Durable and dependable combination of high tensile strength, abrasion resistance, and raschel knitted mesh construction. Well prepared for outdoor UV and moisture exposure with treatments including latex/urethane bonding, and dispersion dying.

DuPont® Kevlar™ Twisted Knotted Netting

Available in #12A twine thickness and 1-1/2” square mesh size. 100% Made in USA. High Performance netting type with very high tensile rating characteristics. Well prepared for outdoor UV and moisture exposure with black urethane bonding treatment.

High Molecular Weight Polyethylene (HMWPE) Twisted Knotted Netting

Available in #18 twine thickness and 1-3/4” square mesh size. 100% Made in USA. High Performance netting type with very high tensile rating characteristics. Well prepared for outdoor UV and moisture exposure with black urethane bonding treatment.

Dacron® Polyester Knotless Debris Fabric

A Debris Fabric product, built from Dacron® polyester in a 1/4” elongated honeycomb mesh construction, 100% Made in USA. Durable and dependable combination of high burst strength and raschel knitted mesh construction. Prepared for outdoor UV and moisture exposure, black dispersion dyed with fire retardant treatment.

High Density Polyethylene (HDPE) Lock Stitch Debris Fabric

A Debris Fabric and 50% shade cloth product, built from HDPE 3-way lock stitch mesh construction, 100% Made in USA. UV resistant, moderate break strength, with fire retardant treatment.

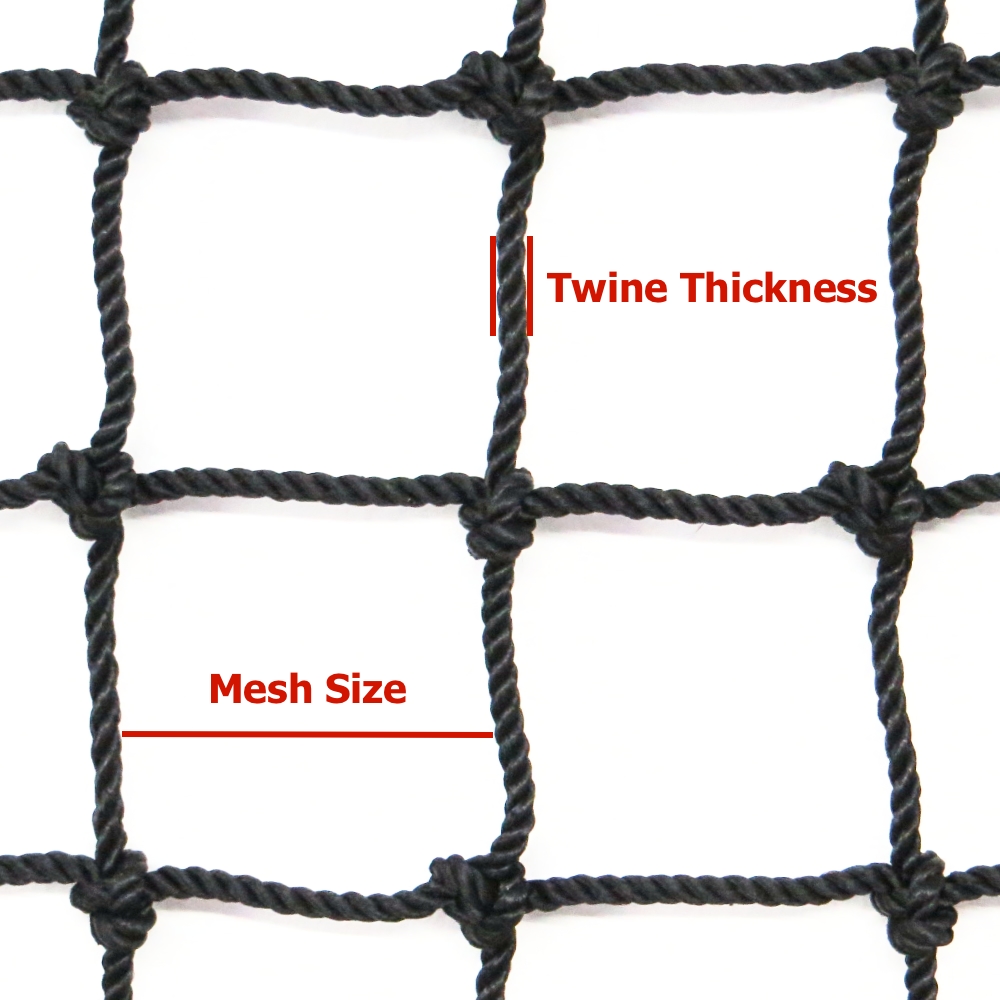

How are the different netting types specified/identified?

There are 3 main identifying characteristics to the different netting types: Twine Thickness, Mesh Size, and Netting Type/Construction.

Twine Thickness is indicated with a number, such as #15, #21, #36, etc. The higher the number, the thicker the diameter of the twine.

Mesh Size is indicated with a measurement of the opening, such as 1”, 1-3/4”, etc. The mesh size of the netting will determine the smallest object that can be contained/blocked by the netting.

Netting Type/Construction is clarified by indicating the material type (such as nylon) and the construction features of how the mesh is created (such as “knotted netting loomed from twisted twine”).

The Gourock store includes a “catch all” Netting By Type page that displays all available netting selections that can be ordered to custom sizing. Each individual netting selection listed on the Netting By Type page provides product details regarding tensile ratings, mesh specifics, and netting construction details - including specification sheets and product images. In addition, each netting choice also conveniently includes a Custom Netting Calculator that is specific to the individual mesh selection.

What type of netting do I need?

You need the correct mesh size to block the smallest object you intend on containing, and a twine thickness that correlates with the amount of abrasion, force, or exposure that you expect the netting to be subjected to. We conveniently categorize several categories within our site that help identify typical or recommended netting selections for the application. Gourock specializes in high quality netting materials that are durable, reliable, and are built per-order to custom dimensions. So you are assured that the materials, preparation, and product characteristics are highly dependable. So in most cases once the correct mesh size is selected, the decision is then focused on using netting that is lighter weight in twine, or heavier weight in twine thickness. When choosing the best netting for your project, some factors to consider include:

- Physical strength of the twine

- Visual appearance of the mesh when in use

- Physical weight of the netting as compared to the installation supports

- Expected abrasion and friction during use

- Exposure to UV/wind/elements

- Project budget balanced with netting performance and function over time

Gourock offers professional customer service and assistance with all types of netting-related questions, inquiries, and recommendations. In addition, we offer free netting sample swatches to be mailed out at your convenience. If you are unable to locate an answer for your question throughout our site, absolutely feel free to Contact Us through our email portal or office phone and it is our pleasure to assist!

Can any sizing of netting be ordered?

Yes - our online store incorporates our Online Custom Netting Calculator for all custom netting selections. This is a robust e-commerce ordering tool that allows you direct access to custom nets that are built to your personalized sizing needs. Along with Custom Netting we also include convenient online ordering of Custom Batting Cage Nets, Golf Cage Nets, and Impact Panel Nets. We will always make sure to get in touch with you should we encounter any clarifying questions regarding your custom netting order.

In addition to online ordering, we also offer helpful customer service for your particular custom netting inquiries. There are many unique netting productions, projects, and designs that have been facilitated over the years - in most cases via personal correspondence and assistance. Also, our Company Blog is a helpful online resource for custom netting information as well.

What are the minimum order details for custom built nets?

We have no minimum requirements for producing nets to whatever quantity or sizing needs that you have. You are free to order one single net, and it can be as small in dimension as you require - since netting orders are prepared per-invoice you have a lot of control on what you prefer to be working with.

However, although we don’t have a minimum requirement from the fabrication side of things, there are some minimum billing requirements on different mesh types which deal specifically with pricing:

- Minimum billing rate is 100 square feet for a single net. You are absolutely free to order nets that are smaller than 100 square foot in area - however they will be billed at a starting price of 100 square foot.

- Minimum billing dimension of 4’ on Nylon, Kevlar, and HMWPE nets. You are absolutely free to order nets that are smaller than 4’ in sizing - however they will be billed at the 4’ minimum.

- Minimum billing dimension of 10’ on debris fabric materials (Polyester, HDPE). You are absolutely free to order nets that are smaller than 10’ in width - however they will be billed at the 10’ minimum.

These pricing levels are based on the minimum overhead required on the factory floor to produce any net at all - including factors such as labor, materials, waste, and administration. We do everything possible to keep our production costs efficient and to offer factory-direct pricing to our appreciated customers, and want to ensure that you are still able to source netting made to any sizing needed.

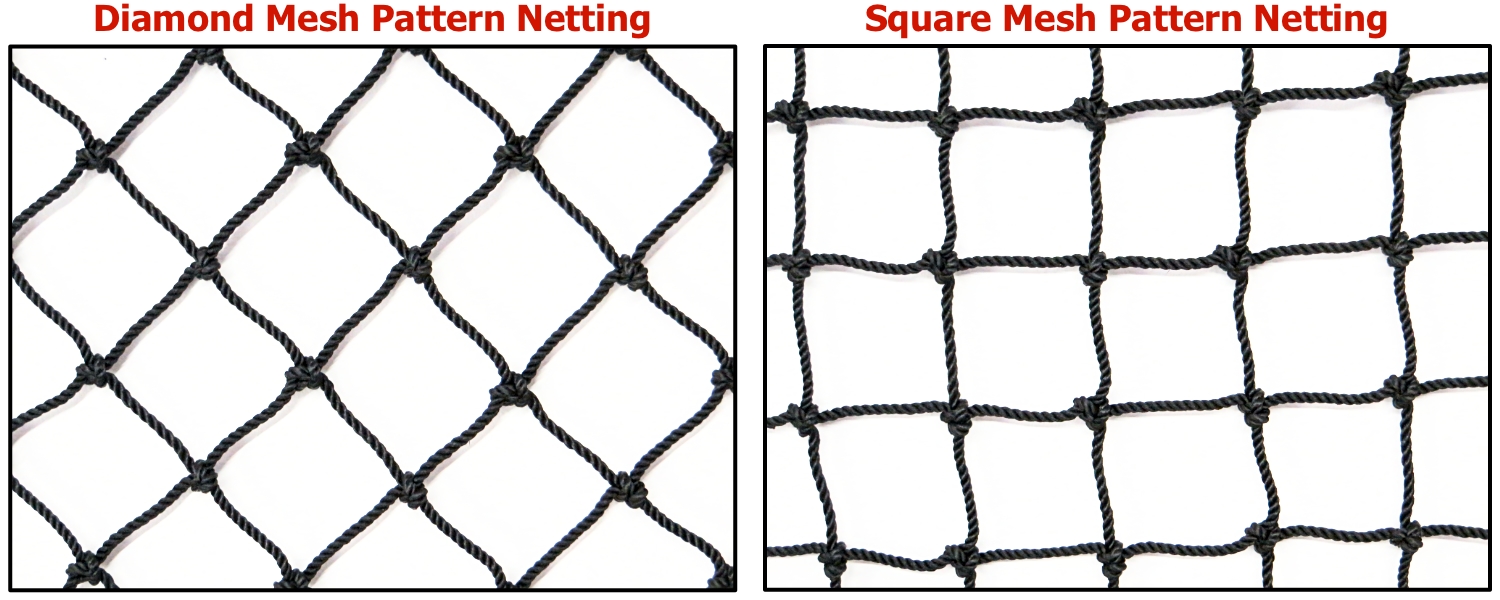

What is the difference between Square Mesh Pattern and Diamond Mesh Pattern?

Most of the twisted-knotted nylon netting selections that we produce are available to be ordered in either a Diamond Mesh Pattern or a Square Mesh Pattern. Aesthetically, one looks like a succession of diamonds and the other looks like a succession of squares. The main difference between the two is that square mesh netting will naturally hang straight and to exact dimensions without a border installed - whereas diamond mesh netting has a lot more “stretch/distortion” and must be held proportionally with a rope bordering in order to be functional to work with in most cases. The reason for these differences is really just a matter of geometry: a square is all 90º angles, while a diamond can be distorted either completely vertically or horizontally.

A great online resource we offer is this helpful Video About Mesh Pattern Choices and Rope Bordering.

Basically, someone should only consider purchasing non-bordered, diamond mesh pattern netting if they are seeking general bulk netting that requires the diamond shape (or, if the diamond is preferred).

Otherwise, it is highly recommended for installation and ease of use to have a rope-border installed around the perimeter, or get a square mesh pattern section of netting. Installation of diamond mesh netting that has no border can be very difficult to accomplish correctly, and usually means much more time involved while working with the netting. We leave the default mesh pattern choice as ‘square mesh’ within the Online Netting Calculators - and offer the diamond mesh pattern as a selectable option.

For context, the twisted-knotted nylon netting is produced on looms that fabricate the netting in a diamond mesh pattern. When converting the material to a square pattern there are some increases in production overhead regarding labor and waste. The result is that the diamond mesh pattern netting has the lowest square footage pricing, whereas square mesh pattern netting selections reflect a higher square footage price due to the more involved fabrication needs. With that in-mind, the slightly higher pricing for square mesh pattern preparation is often a non-issue as compared to the time/energy spent trying to work with diamond mesh netting that has no rope bordering. In many cases choosing square mesh pattern netting is the most user-friendly, functional, and effective approach.

When the netting does have a rope border installed, the diamond mesh pattern is a fantastic product selection and is the recommended product type for large barrier nets at golf driving ranges, stadiums, sports facilities, industrial sites, and hundreds of other barrier netting locations. In fact, diamond mesh pattern netting with a perimeter rope border is an industry standard for most larger area barrier nets.

How are nets bordered or finished around the perimeter edges?

Gourock offers custom netting that can be prepared with or without a finishing edge border around the perimeter of the meshes. The majority of our available netting selections have the options for the netting edges to be Unbordered, Rope Bordered, Rope Bordered with Weighted Rope Bottom, and Webbing/Grommet Bordered.

We have a Netting Borders informational page that does a great job of describing these selections, but some general details of these options are:

Unbordered:

no additional bordering materials at all. When nets are prepared with no bordering at all it can be considered an order for bulk sections of netting - the perimeter of the mesh is the cut edge of the mesh.

Rope Bordered:

5/16” polyester rope bordering installed around the full perimeter of the netting, and sewn/stabilized in-place (machine-sewn on Square Mesh pattern, hand-sewn on Diamond Mesh pattern).

Rope Bordered with Weighted Rope Bottom:

5/16” polyester rope bordering installed on the top edge and both side edges of the netting, with the bottom edge featuring a Weighted Rope installed (segmented weight core).

Webbing/Grommet Bordered:

1-1/2” black polypropylene webbing border around the entire perimeter of the mesh, with #2 brass grommets stamped every 12” (as close as possible to evenly spaced 12” intervals, dependent on the netting dimensions) - exclusively available on Square Mesh pattern netting.

There are also a couple of other bordering types that are very specific to a couple of netting materials that we produce, which are the Kevlar netting and the Polyester debris fabric. These 2 netting types have a cord bordering on them that is different than the rope bordering - and we have this Cord Bordering informational page available to reference in this case.

What are the differences between Golf Barrier Netting and Golf Impact Netting?

Golf barrier netting is used to block and contain golf balls that are hitting the mesh from a distance or reduced velocity - such as nets use to surround driving ranges, protective nets installed along fairways, and golf ball protective nets for windows and solar panels. We specialize in premium golf barrier netting productions, featuring the highest quality 1” mesh size DuPont® type 66 tarred twisted-knotted nylon netting.

Golf impact netting is used to block and contain golf balls that are impacting the mesh from a close range - such as in golf cage nets, golf hitting nets and impact panels, and property protection areas that are subjected to full velocity ball speeds. Gourock supplies 3/4” mesh size DuPont® type 66 twisted-knotted nylon netting for golf ball impact applications.

All golf ball barrier/impact netting selections from Gourock are 100% Made in the USA, and to the customized sizing that you need for your project. As you are making a decision between which circumstance you’re in, consider these generalities:

1” Golf Barrier Netting the preferred choice for ball impacts that are generally further than 15-20 yards

3/4” Golf Impact Netting the preferred choice for ball impacts that are generally within 15-20 yards

Broadly speaking, use the tarred 1” nylon netting if you are doing a project that is large area coverage such as driving range nets or similar. Use the 3/4” nylon netting if you are doing a project that is expected to contain a full speed golf ball driven right into it from a close distance.

Can your netting be used for outdoor and indoor applications?

Yes. All of the netting materials that we produce and supply are very well prepared for full-time outdoor usage, and are excellent for indoor installations. There are varying preparation procedures for the different materials and netting types, but all are subjected to thorough finishing and final processing steps to ensure dependability in both outdoor and indoor environments.

What is the average functional life expectancy for different netting types?

There are 2 primary factors that ultimately affect the effectiveness and strength of outdoor netting over time, under normal usage. These factors are abrasion/friction from wear-and-tear, and sustained continuous exposure to UV light. For nets that are installed indoors there is no effect from UV exposure, so the sole factor in this case is abrasion/friction from wear-and-tear.

Regarding longterm UV exposure, since the environment of every location is unique - and many regions have vastly varying annual sunlight considerations, here is a very general ‘ballpark’ summary of how different twine thicknesses of Type 66 Twisted Knotted Nylon Netting usually perform:

#12 bonded (.062" diameter, 100 lb./tensile):

average expectation to maintain over 50% of original tensile strength for a period of 3 years, with typical average replacement time of 5 years

#12 tarred (.062" diameter, 100 lb./tensile):

average expectation to maintain over 50% of original tensile strength for a period of 5 years, with typical average replacement time of 7 years

#15 bonded (.065” diameter, 125 lb./tensile):

average expectation to maintain over 50% of original tensile strength for a period of 5 years, with typical average replacement time of 7 years

#18 tarred (.069” diameter, 191 lb./tensile):

average expectation to maintain over 50% of original tensile strength for a period of 10 years, with typical average replacement time of 10-12 years

#21 bonded (.079” diameter, 210 lb./tensile):

average expectation to maintain over 50% of original tensile strength for a period of 7 years, with typical average replacement time of 9 years

#36 bonded (.0985” diameter, 350 lb./tensile):

average expectation to maintain over 50% of original tensile strength for a period of 10 years, with typical average replacement time of 10-12 years

#72 bonded (.138” diameter, 665 lb./tensile):

average expectation to maintain over 50% of original tensile strength for a period of 12 years, with typical average replacement time of 12-15 years

The average replacement times for different twine thicknesses are anecdotal estimates based on typical experience - and there are hundreds of nets that we have supplied that far outperform the average. Environmental exposure regarding total UV, movement from wind, abrasion from usage, and materials used to install/suspend the netting all play a part in the overall integrity of the netting over time.

Regarding abrasion and friction due to wear-and-tear and usage - thicker netting twines will inherently have a higher expectation of impact durability over time (due to having more material and larger knots). All of netting materials we supply are very abrasion resistant and perform excellently with regards to usage factors. One of the great benefits of using a netting material like nylon is that it has an optimal combination of high tensile rating and abrasion resistance, which allows even thinner twines to perform dependably. We specialize in premium netting materials such as Type 66 nylon - which has been tested to retain the highest percentage of strength over time as compared to standard type 6 nylon, polyester, and polypropylene. We always offer free netting sample swatches to be mailed out for your in-hand inspection, which can be helpful for your product making decisions.

What color selections are available for different netting types?

All of the custom nets that we have available in our current product line are black in coloring exclusively. There are 2 netting choices that do also offer a white color option, which are the 210D/80 X 1” knotless nylon netting and the 210D/120 X 2” knotless nylon netting (which can be ordered black or white in color).

If you are a vendor or industry client that orders twisted-knotted nylon netting at wholesale volumes, we can accommodate mesh that is loomed from scratch to be in a white coloring. Wholesale volume orders are typically 300+ lbs of nylon netting per invoice, depending on the minimum amount of weight required to produce a custom bale of netting for the job. Always feel free to get in touch with us directly if you have inquiries into wholesale netting fabrication and supply, or other large volume projects that call for more customized twine/mesh/color specifications, and we can correspond/quote you on possible options for your consideration.

Do you offer netting repair services or sell used netting?

We do not offer repair services or supply used netting. All materials that we ship are new/unused product that are generally prepared per-order. Over the course of business there are occasions in which we have some stock of new netting that we list on our Sale & Clearance Netting page, allowing for some attractive pricing deals on materials that we are liquidating.

And while we do not offer netting repair or modification services, since we do offer netting to be ordered to any sizing - and also offer some helpful Accessories such as spools of Nylon Twine and length of Polyester Rope - you can always efficiently source repair materials that you can then use to patch, lace, or seam your netting as needed.

Do you have specification sheets available for the different netting and mesh products you supply?

Yes - we do have the specification sheets for each of the types of netting options used for custom productions, and they are conveniently posted online for reference if needed. Specification sheets provide details regarding mesh construction, twine characteristics, and other pertinent information regarding a particular netting product. Since specification information primarily pertains to how the netting is factory manufactured, there are some notations about mesh depth/length that are specific to the fabrication of the material directly off the loom (and may not be applicable to finished cut-and-sewn product). Here are the links to the specification sheets for each netting selection:

#15 X 3/4" Twisted-Knotted Nylon Netting

#21 X 3/4" Twisted-Knotted Nylon Netting

#12 X 1" Twisted-Knotted Nylon Netting

#18 X 1" Twisted-Knotted Nylon Netting

#12 X 1-3/4" Twisted-Knotted Nylon Netting

#21 X 1-3/4" Twisted-Knotted Nylon Netting

#36 X 1-3/4" Twisted-Knotted Nylon Netting

#72 X 1-3/4" Twisted-Knotted Nylon Netting

#15 X 4" Twisted-Knotted Nylon Netting

#36 X 4" Twisted-Knotted Nylon Netting

210d/80 X 1" Braided-Knotless Netting

210d/120 X 2" Braided-Knotless Netting

#12 X 1-1/2" Twisted-Knotted Kevlar Netting

#18 X 1-3/4" Twisted-Knotted HMWPE Netting

1/4" Polyester Debris Fabric Netting

HDPE 50% Shade Cloth Netting

I have some unique sizing, shape, or design needs for my nets - how can I have those features included?

Custom nets and netting productions from Gourock can incorporate many unique features, characteristics, and design details. For instance, many custom netting orders include design features such as tapered shapes, notches, additional rope rib-lines, bordering and finishing needs, and a host of other personalized requests. Netting that needs to have some extra consideration into the design is absolutely available, and simply send us an email through the Contact Page with your details. The contact page also allows you to upload files such as sketches, diagrams, and photos - and it is our pleasure to correspond with you about your custom netting needs, and get some pricing quotes prepared specifically for your custom net project. Gourock specializes in custom netting productions, including nets that are quite unique and personalized. Our Company Blog is a great online resource to view many examples of custom netting productions that we have built and shipped over the years for many types of applications.

CUSTOM CAGE NETS

What are custom cage nets, and what are they typically used for?

Custom cage nets are 3-dimensional netting designs in which sides, ends, and ceiling areas of mesh are all seamed together into a ‘box-style’ configuration. In our store we offer a couple of very popular products this category: Custom Batting Cage Nets and Custom Golf Cage Nets.

Batting Cage Nets are used for baseball and softball batting practice, pitching practice, and general ball containment during training sessions. Also known as Batting Practice Tunnels, these types of nets feature both side walls, both end panels, and the upper ceiling netting all seamed together with rope bordered edging. Batting Cage Nets are produced as a completely enclosed containment area to the specified Height X Width X Length required for the project. Gourock’s Custom Batting Cage Netting product page provides additional details and online ordering tools.

Golf Cage Nets are used to contain directly driven and hit golf balls from a close range distance. The use of Golf Cage Netting is popular for golf swing training and practice, pro-shop and golf simulator ball containment needs, indoor golf training, and other similar applications that require golf ball catch-and-capture. Golf Cage Nets feature both side walls, back end panel, and the upper ceiling netting all seamed together with rope bordered edging. The front end is “open” to be driving and hitting from (into the cage net) and the resulting design is built according to the specified Height X Width X Depth noted for the order. Gourock’s Custom Golf Cage Netting product page provides additional details and online ordering tools.

Because netting is such a useful ball containment solution for a wide variety of sports and training needs, there are many multipurpose uses for Batting Cage Nets and Golf Cage Nets. Products such as Batting Cage Nets are also popular for cricket and general ball containment needs - and products like Golf Cage Nets are commonly used for kicking and shooting training for various sports as well.

Yes - our online store offers Batting Cage Net Calculators and Golf Cage Net Calculators that allow for any custom sizing dimensions to be entered and ordered. There are some additional production design options that are selected while adding netting to your shopping cart as well. For instance, batting age nets will offer a few different finishing border choices for the bottom of the netting - and also offer independent divider panel net options for wider cages. Golf Cage Nets are commonly utilized in conjunction with a secondary layer of baffle netting called an Impact Panel - and there are a couple of optional selections available to choose from.

What netting types are used to build custom enclosures and cage nets?

Custom Batting Cage Nets are constructed from DuPont® type 66 twisted-knotted nylon netting, in a 1-3/4” diamond mesh pattern. There are twine thickness selections of #21 (210 lb. tensile), #36 (350 lb. tensile), and #72 (650 lb. tensile) available to select from.

Custom Golf Cage Nets are constructed from DuPont® type 66 twisted-knotted nylon netting, in a 3/4” diamond mesh pattern. There are twine thickness selections of #15 (125 lb. tensile) and #21 (210 lb. tensile) available to select from. The optional impact panel netting is produced from #21 X 3/4” twisted-knotted nylon.

Can batting cage nets also contain golf balls?

No they cannot, as the 1-3/4” mesh size netting that is used for Batting Cage Netting is too large to block or contain golf balls. Golf ball impact containment (close range full velocity) requires a smaller mesh size of 3/4”. Batting cage nets are great for usage with containing balls that are 2”+ in diameter, making them popular for baseball, softball, cricket, and similar multi-sport uses - but not for golf ball containment.

If you want to utilize an area of a batting cage net for golf hitting purposes, a popular approach is to hang a secondary layer of 3/4" nylon netting (within the enclosure net). This is often accomplished by using individual netting panels of golf impact mesh, or by having a golf cage net constructed that can act as a 'golf net insert' to encompass an entire back end area in golf ball containment netting.

Do cage nets come with frames or associated installation parts?

Gourock specializes in the custom netting productions specifically - we don’t include frames, fittings, or installation parts with the cage nets.

Custom enclosure netting (such as batting cage nets and golf cage nets) can be installed within a wide variety of popular methods. Some examples include external framing structures, support poles, tensioned cable suspension, or track systems. Since we construct custom cage nets according to the dimensions needed, you can order the netting made to the sizing that will properly fit an existing framing structure (or one that will be constructed for the project).

There is a very popular approach to installing batting cage nets that is known as a “cable suspension technique”. This is when a series of tensioned wires are spanned between supports, and the ceiling of the netting is clipped underneath - effectively suspending the net from the wires and allowing the netting to hang down to the ground. We do sell some of these parts that are used for cable suspension installations, and they are available to view on the Hardware/Accessories page and the Cable Suspension Kit page of our site.

How long does it take to build and ship a custom cage net?

Custom batting cage nets and golf cage nets are typically built and ready to ship out within 7-10 working days of the order being placed. If the overall sizing of the enclosure is extra large in volume, or there are multiple cage nets required to be built, production lead-time can be estimated for you based on the current fabrication queue. Always feel free to Contact Us directly should you have clarifying questions on current lead-times.

I have more customized design needs for my cage netting project, how can I have those features included?

Custom cage nets from Gourock can incorporate lots of unique features, characteristics, and design details. For instance, many custom cage nets include entrance door flaps, tapered shapes, additional rope-lines, mesh pattern or mesh sizing requirements, and a host of other personalized requests. Netting that needs to have some extra consideration into the design is absolutely available, and simply send us an email through the Contact Page with your details. The contact page also allows you to upload files such as sketches, diagrams, and photos - and it is our pleasure to correspond with you about your custom cage needs, and get some pricing quotes prepared specifically for your netting project. Gourock specializes in custom netting productions, including netting enclosures and cage nets. Our Company Blog is a great online resource to view many examples of custom cage nets that we have built over the years.

HARDWARE AND ACCESSORIES

What types of netting installation hardware items do you offer?

Many netting installations are accomplished by using tensioned cables/wires that span between robust supports, and then the netting is subsequently clipped to the wire. This is often known as a ‘cable suspension method’ and is a popular approach for netting panels, divider nets, and netting enclosures. Within our product line we offer cabling rigging parts that center around 3/16” aircraft cabling and the associated materials that are typically used with it. Our hardware product line includes spools of galvanized aircraft cabling, turnbuckles, cable clamps, snap-hook clips, and some multipurpose accessories such as spools of nylon twine and bulk lengths of polyester rope.

We do not currently stock or supply eyebolts, poles, posts, ground anchors/sleeves, or other similar structural components. However, the cable rigging parts that we do have available can ordered and shipped along with the nets - allowing for you to source a good amount of the netting installation products at once.

What are your hardware parts usually used for?

Cable rigging parts are used to tension lengths of wire between strong/rigid attachments points such as poles, posts, walls, beams, and rafters. The tensioned wire acts as a level attachment plane that netting can then be clipped to and suspended from. This is a popular approach for outdoor barrier nets, ceiling protection nets, divider panel nets, cage enclosure nets, and many other multipurpose projects in which dependably spanning netting between supports is the end goal. For instance, using a cable suspension installation method is most popular for golf driving range nets and property protection nets, pickleball court divider nets and gymnasium divider netting needs, batting cage and golf cage nets, athletic stadium containment nets, and hundreds of other custom netting installation locations.

Utilizing a tensioned cable for your netting installation technique is a great way to achieve a level/even fit and appearance of the netting, to distribute the weight of the netting evenly along the run, to potentially slide the netting “curtain style” along the cable if preferred, and to maximize the coverage area of the netting within the intended space. It’s an efficient method that is tremendously popular for netting projects of all sizes, and here are some informational pages on our site that aid in describing how these hardware parts are often utilized:

Netting Installation Context

Installing Tensioned Cabling

GENERAL QUESTIONS

Where are your nets made?

Gourock is proud to offer netting products that are manufactured and shipped directly from our factory partner in Washington State. We primarily specialize in 100% Made in USA netting productions and materials, with the majority of our products also utilizing a local supply chain for premium raw materials as well. Custom nets are prepared individually per-order, and depart directly from the factory shipping bay to your door.

How long does it take to receive my order?

Netting orders are produced per-invoice, and are custom fabrications that have mandatory production lead-times in order to be ready to ship. Production lead-times vary based on the amount of material, order features, current production queue, and seasonality.

Netting orders are completed for shipping as quickly as possible, and frequently depart on the shorter end of the estimated production lead-time. Phone or email inquiries regarding lead-times are accepted through the company contact page. Please note that business days are Monday-Friday (weekends and holidays do not count as production days).

Smaller or average volume orders of bulk netting (unbordered sections of mesh) are typically finished and ready to ship out within in 2-5 business days of your order being processed.

Higher volumes of bulk netting, as well as average orders of netting that has bordering added to the perimeter (rope border or webbing border) are typically completed and ready to ship out within 5-7 business days of your order being processed.

Larger scale netting orders, highly customized constructions, commercial volumes of material, and multiple quantity fabrications have fabrication lead-times that can be estimated per-invoice or quote, and can be 10+ business days to be completed and ready to ship. Depending on the current production queue, larger volume netting orders may take up to 3 working weeks (+/-) in some cases.

Examples of nets that may take a couple weeks to be ready would be about 2000+ square foot in area or larger. Netting orders of 4000+ square foot in area may be around the 3 week mark (+/-), depending on the current queue.

Do you offer installation services or on-site work?

We do not. Gourock exclusively specializes in the supply of nets, custom netting products, and some associated hardware accessories. We do not offer on-site work, installation services, or project design engineering. That said, with many years of netting supply experience we do offer as much anecdotal advice and feedback as possible while corresponding about netting projects. Many of our clients are construction general contractors as well as fencing installation firms - both of which are very commonly used for structural aspects and installation services.

Do you sell poles, posts, frames, or framing parts?

No - Gourock specializes in netting production and supply, and we do not currently sell or supply poles, posts, frames, or fittings. The nets that we supply can be installed within a wide variety of structural designs and materials - so whether you have existing supports or are constructing from scratch, from Gourock you can order the custom sizing needed for most any coverage area.

Many netting installation techniques involve spanning tensioned wires or cables between robust connection points, and clipping the netting to the cabling. This approach is popular and effective for both netting panels and netting enclosures alike. We do carry a product line of cabling rigging parts that are commonly used for this type of approach on our Hardware and Accessories category.

Where can I find poles or posts for my netting project?

Generally speaking, getting in touch with local supplier of fencing materials (or a regional tubing distributor) is a great resource. There is also an online marketplace for poles, posts, anchors, and frames - generally from firms that specialize in tubular steel parts and similar materials.

What is the return/exchange policy on purchases?

Please visit our Return Policy page for details. Due to the different production, specialization, and manufacturing characteristics of Gourock's diverse product line, there are unique guidelines regarding returns and exchanges of purchased items. Please carefully review the Return Policy information, and feel free to contact us prior to purchasing if you require additional context.

How are nets packaged and shipped, and where can they be shipped to?

Most nets are folded-and-packed in a cardboard shipping box for UPS services (for parcels up to 150 lbs.). For netting productions that are overweight we ship via LTL trucking service (such as R&L Carriers, XPO Logistics, or Oak Harbor Freight).

We generally ship to North American locations, however we do facilitate a number of international shipments as well (via UPS Worldwide). The Gourock online store allows for international shipment locations to be selected during checkout.

Please also reference the Shipping Policy page to get some more context on shipment information, and should you have some more specific shipping questions about your particular netting project please Contact Us and we can assist.

Are there warranties applied to any of your custom netting products?

Tarred 1”mesh twisted-knotted nylon netting panels carry pro-rated UV warranties of 10 years for the #18 twine thickness, and 5 years for the #12 twine thickness. Tarred 1” mesh nylon netting is popularly used for high quality barrier netting projects including golf driving ranges, golf courses, property protection, stadiums, industrial sites, landfills and recycling facilities, retainment ponds, bird exclusion situations, solar panel and window protection, and dozens of other similar containment and protective netting applications. To access the pro-rated warranty documentation, see these site links for #18 X 1” tarred nylon netting and #12 X 1” tarred nylon netting.

What purchasing opportunities do you offer for municipal, organizational, industrial, and vendor-focused clientele?

Gourock is a netting supplier to hundreds of organizational clients, many of which do business via purchase order and associated accounting administration. It is always our pleasure to develop netting supply relationships with all types of B2B, municipal, scholastic, governmental, and industrial customers. Please contact us directly should you require a formal quotation, W9, vendor information submittal, or other purchasing/account details. We also accept payment cards and mailed-in check payments for quotes as well. We consistently strive to offer organizational customers premium netting materials and professional service, and look forward to working with you!

Can I have samples of the different netting types mailed to me?

Yes! Gourock offers free netting sample swatches - mailed to your USA mailing address location of choice. Our Contact Page conveniently offers a selection to request free netting samples. Always feel free to get in touch with us regarding the netting types you are interested in (along with the preferred name/address to mail them to) and we’ll get them promptly administered for you.

Do you accept photos of our installation to be posted on your website?

Absolutely! We encourage customers to send photos of their netting installations to be posted on the website and company blog. This provides a great opportunity for you to highlight your organizational or individual netting projects - emailed photos are always very appreciated. And of course, more visuals are helpful to everyone involved in e-commerce, especially customers doing product research into netting products.