Customized netting projects are facilitated and supplied by Gourock.com every business day, all year long. Netting is a very functional and dependable solution for a huge variety of applications and uses. Ranging in scope from athletics to industrial needs, and from animal control to home-projects, there is a seemingly unlimited array of purposes and situations that can greatly benefit from nets and netting products. We certainly see it all! And of course, years and years of customized netting supply and design means that Gourock.com can provide you with what you need to be up-and-running.

Although we deal with a wide range of netting materials and constructions throughout our product line, with rare exceptions tje customized netting projects are produced from the highest-end nylon netting available – DuPont® Type 66-728 Twisted/Knotted Nylon. Hand-built and built to most any spec that you require, you can have netting panels, enclosures, and specialty applications supplied to you from a variety of netting twine thicknesses and mesh sizes.

There are some really great examples of custom netting enclosures and netting panels noted on their respective pages on the Gourock.com website, and to further assist you with your netting research we’d like to share some recent products supplied and shipped out within the last month:

ABOVE: This is a customized netting formation that was basically a 60′ X 100′ “box” created from some Dacron® rope-bordered netting panels, and then topped-off with a custom top-net that was to be installed within a peaked-roof. This was supplied and drawn-up/produced for a customer that was installing a baseball training facility at their own property – and they had a pretty specific request on how they preferred the netting to overhang on the end-panels when installed. Using the 1-3/4″ diamond mesh knotted nylon netting works out very well for baseball netting applications like this one.

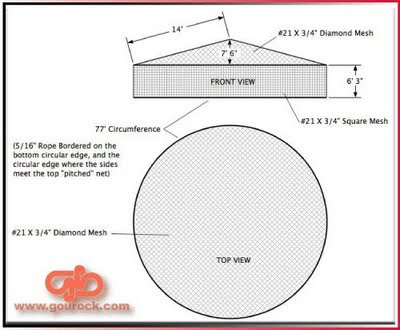

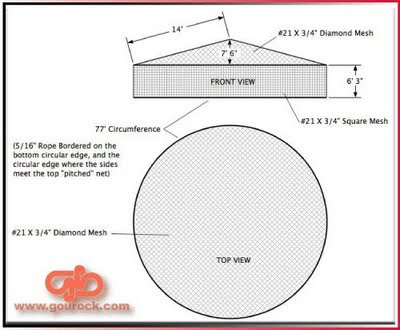

ABOVE: This is a 77′ circumference circular tent-style netting production that was shipped over to Hawaii, and was designed off of the customer’s specs regarding their yurt. This #21 X 3/4″ knotted nylon netting project has the purpose of being installed over the top of their yurt in order to protect the structure’s walls and canopy from the effects of wild storms and winds prevalent in the their Hawaiian location. Utilizing the 3200 lb./test Dacron® ropes, and the 241 lb./twine DuPont® nylon small mesh netting, results in a very strong and dependable reinforcement barrier against the elements. All while being very user-friendly and very manageable to work with.

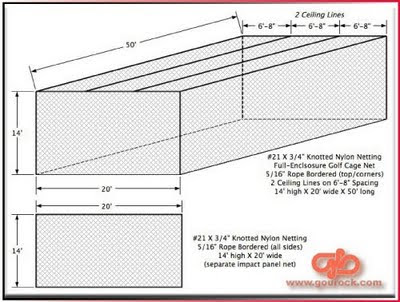

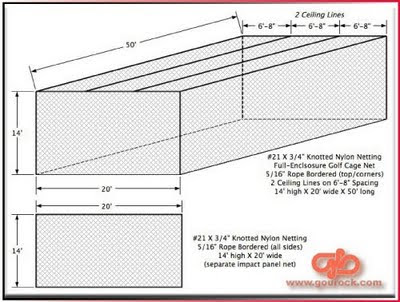

ABOVE: Customized golf netting enclosures are consistently supplied and produced for commercial training facilities, universities, pro-shops, and residential installations. Often, the overall area to be enclosed is to act as a multipurpose sport training area, and needs to have the capacity to block direct golf ball impacts as well as have the overall area available for larger-scale hitting purposes like baseball and softball. This 14′ X 20′ X 50′ netting enclosure (with impact panel net) is a great example of a multipurpose net enclosure that was produced to accomplish just that. Featuring the thickest available knotted nylon golf impact netting, and additional ceiling lines for maximum support on the top netting, this customized netting enclosure gets the job done for a huge variety of sports and uses.

ABOVE: Maximizing the space available within a building is a concern of most every netting customer. Often, the side walls of a building have different heights than the central-ceiling sections of the building – making a custom shaped netting production inevitable in order to get a great fit and a functional installation. This professional-style custom batting cage net was drawn-up from the customer’s building specs, and then built to shape. Featuring a tapered ceiling/end-panel design which was necessary to match the slope of the building’s roof, this batting cage net was provided to make sure their training facility was able to provide athletes with the best possible space to practice. Not to mention that the #36 DuPont® knotted nylon was all Diamond-Shield Dipped, and that the enclosure has the built-in impact panel (double-wall end + entrance), 3/8″ Dacron® ropes, and a heavy leadline bottom. This is a good example a high-end professional batting cage net that also utilizes a customized tapered build based on a customer’s specific available area.

-Josh Grzyb @ www.gourock.com